A Lifetime Commitment to Responsibility

At Nobis, taking environmental and social responsibility for our products is a lifetime commitment. We strive for innovation, carefully considering all elements throughout the development process, from initial design concept until the product reaches your hands. Our teams design with purpose, ensuring every product delivers high performance while embodying sustainability. Designed for durability, longevity, and timeless appeal, Nobis products are made to endure—both physically and emotionally. Through Nobis Conscious Performance, we champion Designing for Durability: crafting products that last not just because they're built to, but because they’re loved.

Nobis Conscious Performance: Performance Meets Sustainability

At Nobis, we believe that sustainability should never come at the expense of quality or performance. With durability and longevity at the heart of our design philosophy, we’re committed to seamlessly integrating high performance with responsible practices. Our goal is simple: create products that excel in the elements and endure over time—without compromise.

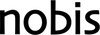

Our Conscious Performance framework guides this mission through four interconnected pillars: Culture, Business Models, Product, and Process. It all begins with Culture—fostering a mindset of continuous improvement that drives innovation, operational excellence, and long-term impact.

Preferred Materials

Since joining Textile Exchange in 2022, Nobis has been part of a global network of over 800 brands, retailers, and suppliers, collectively working to accelerate the adoption of preferred, lower-impact materials throughout the textile industry. To guide our material choices, we use the Preferred Fibers & Materials Matrix developed by Textile Exchange, a trusted industry standard for assessing the environmental performance of alternative fibers.

Phasing out PFAS for Safer Chemicals

In 2022, Nobis took a significant step toward cleaner production by introducing PFAS-free water-repellent treatments into our product line. Replacing legacy fabric treatments and systematically phasing out older PFAS-based inventories has been a complex, multi-year effort. We’re proud to announce that in 2025, PFAS-based water-repellent treatments have been eliminated from new fabric production.

To ensure our fabrics remain free from harmful chemicals, we require that all materials are either bluesign® approved or STANDARD 100 by OEKO-TEX® certified. These internationally recognized standards restrict the use of hundreds of hazardous substances and now include a complete ban on PFAS in textiles.

We continue to collaborate closely with our suppliers to identify and develop high-performance alternatives that offer durability without compromise—ensuring safer, lower-impact treatments that align with our sustainability values.

Progress Through Recycled Materials

Recycled fibers are central to our sustainability strategy, helping reduce dependence on virgin and non-renewable resources. In 2022, we introduced our first recycled fabrics—Recycled Crosshatch and Recycled 3L Micro-Denier—each made with a minimum of 40% recycled polyester derived from post-consumer plastic bottles.

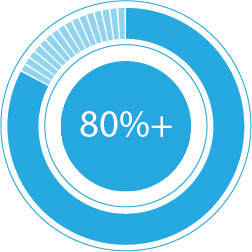

This shift has continued to scale across our collections. Today, over 80% of our primary raw materials, including both fabrics and insulations, contain at least 20% recycled content.

Love it for Longer: Extending the Life of Every Garment

One of the most impactful ways to reduce textile waste is by extending the life of your garments. Rather than sending items to landfills or allowing them to pollute natural environments, we encourage responsible use - through repair, resale, donation, or recycling. At Nobis, we are continuously working to improve the recyclability and end-of-life impact of our products to ensure they can be disposed of safely and respectfully when their journey ends.

Product Care

We design most Nobis products to be machine washable and tumble dryable, making care easy and convenient. Proper maintenance not only keeps your garment looking and performing its best—it also helps extend its lifespan and preserve its value season after season.

Learn how to care for your Nobis jacket

Warranty & Repair

Our lifetime warranty covers repairs for any defects in materials or workmanship, free of charge. For wear and tear beyond warranty coverage, we encourage contacting us or working with local repair or alteration professionals to keep your piece in circulation and out of landfills.

NEXT by Nobis

Nobis garments are crafted for long-term wear, making them ideal for second lives. Our peer-to-peer resale program, NEXT by Nobis, enables customers to resell their pre-owned Nobis products through a secure, authenticated platform. The result? A more circular wardrobe with maximum value and minimal environmental impact.

No Cold Shoulder

Our annual No Cold Shoulder campaign invites customers to donate gently used jackets from any brand. In collaboration with trusted charities across Canada, we ensure these coats reach individuals and families in need. Want to give back year-round? Explore No Cold Shoulder for a list of partner organizations or connect with your local charity to donate directly.

Our progress to a more sustainable future

-

-

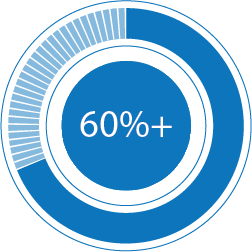

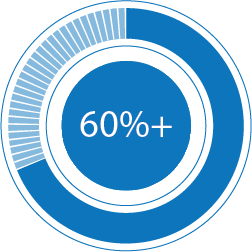

60%+ of primary raw materials are developed with a minimum of 50% recycled content.

-

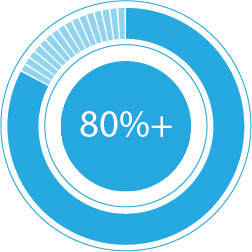

80%+ of primary raw materials are developed with a minimum of 20% recycled content.

-

-

-

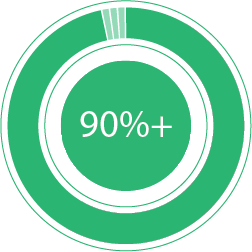

90%+ of primary materials are certified according to Bluesign or Oeko-Tex standards.

-

90%+ of primary materials are certified to at least one lower impact standard.

-

Partnerships for climate and nature

We have partnered with local and international organizations to help advance our sustainability efforts at different stages of the product lifecycle.

Canopy

Canopy’s mission is to protect the world’s forests, species, and climate, and to help advance Indigenous communities’ rights. For nearly 25 years, Canopy has worked collaboratively to transform unsustainable supply chains, catalyze innovative solutions, and keep the world’s vital forests standing. Canopy works collectively with some of the world’s largest fashion, food and beverage, and beauty and care brands, as well as publishers and printers, to bring forest-saving solutions from the margins to the mainstream. Nobis has partnered with Canopy to join their mission to protect the world’s forests through our approach to procurement of paper, packaging, and fabrics.

Trove

Trove is a leading circular economy technology company that offers brands an ecommerce solution to capture their secondhand sales. In Fall 2022, Nobis launched a Peer-to-Peer resale platform NEXT by Nobis, offering customers in Canada and the United States to resell their preloved Nobis products through an authenticated process. Every Nobis product available through NEXT by Nobis has been verified by our team members to ensure products traded through the platform are authentic Nobis products. Resale, an important part of Nobis sustainability journey, extends the lifespan of the products by keeping them in circulation and prevents them from becoming waste prematurely. Resale promotes a culture of responsible consumption, where customers consider the environmental impact of products through reuse, whether they are selling or buying.

To learn more about Trove, please visit: trove.com

Brands for Canada

Nobis has partnered with Brands for Canada, a Canadian charity that helps brands donate their surplus inventories to people in need nationwide. BFC helps millions of Canadians in need through partnerships with charities, schools, and brands across Canada, and has distributed hundreds of millions worth of donated merchandise across the country to communities in need. These donations help people who have limited access to essentials such as warm clothing and enables products to circulate longer, preventing usable products from being discarded as waste prematurely. Products unfit for donating are diverted through BFC’s recycling partner.

DHL

Nobis has partnered with one of our primary service providers, DHL Express, to utilize sustainable aviation fuels (SAF) via the GoGreen Plus service to deliver part of our shipments. By investing in sustainable aviation fuel, DHL reduces the CO2e emissions associated with their shipments. SAF is currently the primary route to reducing carbon emissions in aviation, and embracing SAF is not only essential for meeting sustainability goals but also paves the way towards a greener future in the air transportation industry. To learn more about the GoGreen Plus service, visit: DHL